|

|

Home | Profile | Quality | Technical Info | Products | Standard Assemblies | Laboratory Glassware | Glass Jacketed Vessels | Glass Tubes | PTFE Lined Products | PTFE Labware | Plastic Labware | Contact Us |Feedback | Sitemap

Lighting Glass

A: Lead Glass Tubing

Property of 13% lead Glass Tube

| No. | Chemical And Physical Performance | Data | Unit |

| 1 | Coefficient of Expansion Rate | 9.3 +/- 0.5 | 10-6K-1 |

| 2 | Softening Point | 660 +/- 10 | oC |

| 3 | Temperature for the specific electrical resistance of 108 omega. cmtk100t | >= 240 | oC |

| 4 | Contents of lead | 11.5 | % |

| 5 | 20oC Density ro | 2.66 +/- 0.05 | G/CM3 |

Specification of 13% lead Glass Tube

| Diameter | Wall Thickness | Straightness | |||

| Outer Diameter | Tolerance | Wall Thickness | Tolerance | Skewness of W.T. | |

| 2.5 ~ 2.8 | 2.65 +/- 0.15 | ||||

| 4.0 ~ 4.3 | 4.15 +/- 0.15 | ||||

| 8.95 ~ 9.45 | 9.20 +/- 0.25 | ||||

| 9.0 ~ 9.5 | 9.20 +/- 0.25 | ||||

| 9.2 ~ 9.7 | 9.20 +/- 0.25 | ||||

| 9.7 ~ 10.2 | 9.45 +/- 0.25 | ||||

| 9.75 ~ 10.25 | 9.95 +/- 0.25 | ||||

| 10.25 ~ 10.5 | 10.0 +/- 0.25 | ||||

| 9.8 ~ 10.3 | 10.25 +/- 0.25 | ||||

| 11.4 ~ 11.9 | 10.5 +/- 0.25 | ||||

| 11.5 ~ 12.0 | 11.65 +/- 0.25 | ||||

| 11.6 ~ 12.0 | 11.75 +/- 0.25 | ||||

| 11.6 ~ 12.1 | 11.80 +/- 0.20 | ||||

| 11.6 ~ 12.2 | 11.90 +/- | ||||

| 11.6 ~ 12.2 | |||||

| 11.8 ~ 12.2 | |||||

| 14.0 ~ 14.5 | |||||

| 14.0 ~ 14.5 | |||||

| 14.05 ~ 14.55 | |||||

| 14.8 ~ 15.4 | |||||

| 15.6 ~ 16.2 | |||||

| 16.0 ~ 16.5 | |||||

| 16.2 ~ 16.8 | |||||

| 16.8 ~ 17.4 | |||||

| 17.6 ~ 18.2 | |||||

| 19.0 ~ 19.6 | |||||

| 19.0 ~ 20.0 | |||||

Property of 21% lead Glass Tube

| Chemical and Physical Property | Data |

| Coefficient of Expansion Rate(20oC-300oC) | 91.0 +/- 2 +/- 10-7/K |

| Soften Point | 635 +/- 10oC |

| When the Mass resistance is 100M Omega cm, temperature of TK-100 | >= 240oC |

| Density | 2.83 +/- 0.03g/cm3 |

| Content of Lead | 21% |

Specification of 21% lead Glass Tube

| Diameter | Deviation of Diameter | Wall Thickness | Deviation of Wall Thickness | Skewness of Wall Thickness | Straightness |

| 2.5 ~ 3.2 | +/- 0.10 | 0.60 | +/- 0.10 | 0.10 | |

| 3.2 ~ 4.0 | +/- 0.17 | 0.70 | +/- 0.10 | 0.10 | |

| 4.0 ~ 4.5 | +/- 0.20 | 0.70 | +/- 0.10 | 0.10 | |

| 4.5 ~ 5.5 | +/- 0.20 | 0.90 | +/- 0.10 | 0.10 | |

| 5.5 ~ 6.0 | +/- 0.20 | 1.00 | +/- 0.10 | 0.10 | |

| 6.0 ~ 10.0 | +/- 0.20 | 0.80 | +/- 0.10 | 0.10 | |

| 10.0 ~ 12.0 | +/- 0.20 | 0.80 | +/- 0.10 | 0.10 | |

| 12.0 ~ 15.0 | +/- 0.30 | 1.00 | +/- 0.10 | 0.10 | |

| 15.0 ~ 18.0 | +/- 0.30 | 1.00 | +/- 0.10 | 0.10 | |

| 18.0 ~ 20.0 | +/- 0.30 | 1.30 | +/- 0.10 | 0.10 | |

| 20.0 ~ 25.0 | +/- 0.30 | 1.50 | +/- 0.15 | 0.10 | |

| Other specifications can be made according to customer's requirements | |||||

| Skewness of Wall thickness/one cross section Maximum wall thickness-Minimum wall thickness | |||||

| Limit deviation of our diameter is +/- 0.15. Limit deviation of wall thickness is +/-0.05 | |||||

B: Lighting Bulb and Tubing

Technical data

| Item | Data | Unit |  |

| Coefficient of linear expansion 20/300 | 40.5 +/- 1.0 | 10-6 K-1 | |

| Softening point | 780 +/- 10 | oC | |

| Annealing point | 555 +/- 10 | oC | |

| strain point | 505 +/- 10 | oC | |

| Temperature for the specific Electrical resistance of 108 cm(din52356)tk 100t | > 235 | oC | |

| Thermal stability | > 235 | oC | |

| 20oC Density ro | 2.26 +/- 0.015 | g/cm3 | |

| Water resistance | 1 |

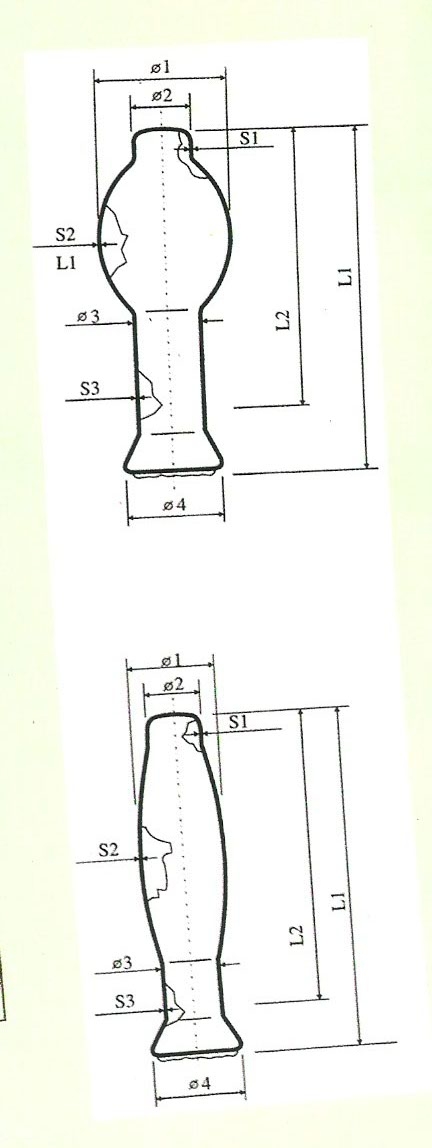

Bulbs for High-Pressure Mercury Light

| Type | Diameter | Length | Well Thickness | Power | ||||||

| L1 | L2 | S1 | S2 | S3 | ||||||

| BT70 | 70 +/- 1.0 | 34 | 36 +/- 1.0 | < 48 | 200+/-5.0 | 165+/-5.0 | 0.6-1.5 | 0.7+/-0.2 | 0.95+/-0.25 | 60 |

| BT75 | 75 +/- 1.0 | 35 | 36 +/- 1.0 | < 50 | 203+/-5.0 | 161+/-5.0 | 0.6-1.6 | 0.7+/-0.2 | 0.95+/-0.25 | 80 |

| BT80 | 80 +/- 1.0 | 34 | 36 +/- 1.0 | < 52 | 233+/-5.0 | 185+/-5.0 | 0.8-1.7 | 1.0+/-0.25 | 1.0+/-0.25 | 1.25 |

| BT90 | 90 +/- 1.0 | 39 | 45 +/- 1.0 | < 64 | 246+/-2.0 | 194+/-5.0 | 0.8-1.7 | 1.0+/-0.3 | 1.05+/-0.3 | 250 |

| BT120 | 118 +/- 2.0 | 46 | 50 +/- 1.0 | < 78 | 310+/-5.0 | 248+/-5.0 | 0.8-1.7 | 1.0+/-0.3 | 1.05+/-0.3 | 400 |

Bulbs for High-Pressure Sodium Light

| Type | Diameter | Length | Well Thickness | Power | ||||||

| L1 | L2 | S1 | S2 | S3 | ||||||

| BT62 | 62 +/- 1.0 | 42 | 42 +/- 1.0 | =66 | 260+/-5.0 | 220+/-5.0 | 1-3 | 0.8+/-0.2 | 1.15+/-0.30 | 100 |

Bulbs for High-Pressure Sodium Light

| Type | Diameter | Length | Well Thickness | Power | |||

| L1 | L2 | S1 | S2 | ||||

| T37.5*108 | 37.5=1.0 | < 60 | 180+/-5.0 | 132+/-5.0 | 1.0-3.5 | 1.0+/-0.3 | 80 |

| T37.5*208 | 37.5=1.0 | < 60 | 208+/-5.0 | 160+/-5.0 | 1.0-3.5 | 1.0+/-0.3 | 80 |

| T46*220 | 46+/-1.0 | < 67 | 220+/-5.0 | 165+/-5.0 | 1.0-3.7 | 1.15+/-0.3 | 100 |

| T46*265 | 46+/-1.0 | < 67 | 265+/-2.0 | 210+/-5.0 | 1.0-3.7 | 1.15+/-0.3 | 250 |

| T46*290 | 46+/-1.0 | < 67 | 290+/-5.0 | 235+/-5.0 | 1.0-3.7 | 1.15+/-0.3 | 400 |

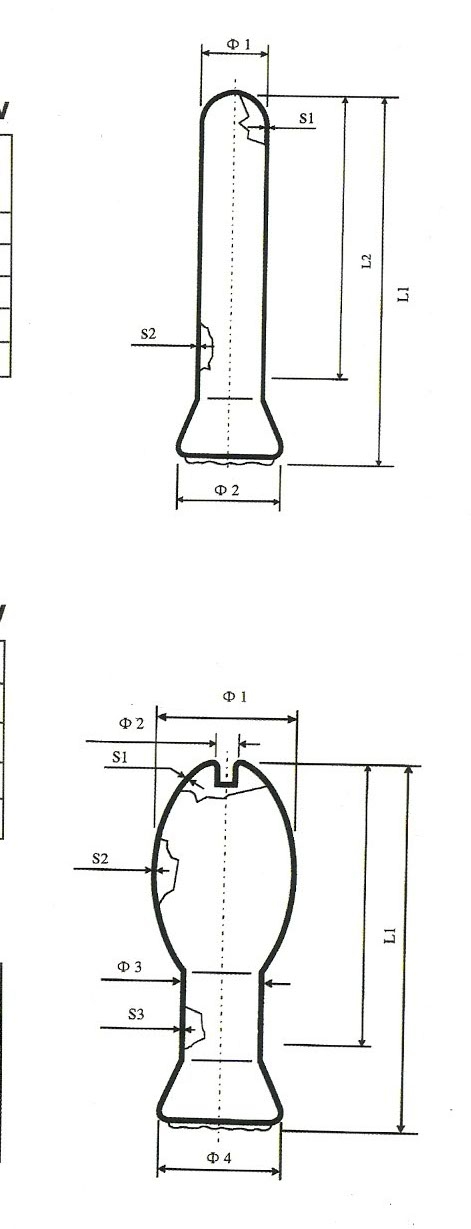

Bulbs for High-Pressure Halogen Light

|

Type |

Diameter | Length | ||||

| 1 | 2 | 3 | 4 | L1 | L2 | |

| ED55 | 55 +/- 1.0 | 5.0 +/- 1.5 | 36 +/- 1.0 | < 52 | 170 +/- 5.0 | 115 +/- 5.0 |

| ED90 | 90 +/- 1.0 | 13.5 +/- 1.5 | 50 +/- 1.0 | < 70 | 250 +/- 5.0 | 193 +/- 5.0 |

| ED120 | 118 +/- 2.0 | 13.5 +/- 1.5 | 50 +/- 1.0 | < 82 | 325 +/- 5.0 | 255 +/- 5.0 |

| Type | Wall Thickness | Power | ||

| S1 | S2 | S3 | ||

| ED55 | 1.0-2.0 | 1.0 +/- 0.3 | 1.15 +/- 0.3 | 100 |

| ED90 | 1.7+/-0.7 | 1.0 +/- 0.3 | 1.15 +/- 0.3 | 250 |

| ED120 | 1.0-2.4 | 1.0 +/- 0.3 | 1.15 +/- 0.3 | 400 |

Special size bulb can be made according to customer's requirement.

Specification of Flare Tube

| Outer Diameter | Wall Thickness | Standard Length | Skewness | Straightness |

| 10.0 +/- 0.25 | 1.0 +/- 0.1 | 1175 +/- 15 | < 0.1 | < 3 o/oo |

| 13.0 +/- 0.25 | 1.0 +/- 0.1 | |||

| 15.0 +/- 0.4 | 1.2 +/- 0.2 | |||

| 17.0 +/- 0.4 | 1.2 +/- 0.2 | |||

| 20.5 +/- 0.5 | 1.2 +/- 0.2 | |||

| 24.0 +/- 0.5 | 1.2 +/- 0.2 | |||

| 26.0 +/- 0.5 | 1.4 +/- 0.2 |

Specification of Exhaust Tube

| Outer Diameter | Wall Thickness | Standard Length | Skewness | Straightness |

| 4.1 +/- 0.2 | 0.8 +/- 0.1 | 1175 +/- 15 | < 0.1 | < 3 o/oo |

| 4.4 +/- 0.2 | 0.8 +/- 0.1 | |||

| 5.0 +/- 0.2 | 0.8 +/- 0.1 | |||

| 6.0 +/- 0.25 | 1.0 +/- 0.1 |

Package

| Article No. | Size of Carton Box (mm) | Packing Quantity |

| BT90 | 600 x 400 x 255 | 5 x 7=35 |

| BT120 | 600 x 400 x 315 | 4 x 5=20 |

| T37.5 X 180 | 600 x 400 x 185 | 7 x 11=77 |

| T37.5 X 208 | 600 x 400 x 215 | 7 x 11=77 |

| T46 X 220 | 600 x 400 x 225 | 6 x 9 =54 |

| T46 X 265 | 600 x 400 x 270 | 6 x 9 =54 |

| T46 X 290 | 600 x 400 x 295 | 6 x 9 =54 |

| ED55 | 600 x 400 x 345 | 154 |

| ED90 | 600 x 400 x 265 | 5 x 7=35 |

| ED120 | 600 x 400 x 330 | 4 x 5=20 |

Copyrights Reserved 2001-2007 by Garg Scientific Glass Industries. |